Rocket Lab finally pulled the cover off its Neutron rocket, a medium-lift vehicle that CEO Peter Beck calls “a rocket of 2050,” as the company looks to take a greater share of the launch market currently dominated by SpaceX.

This is the first major update on the project from the company since Neutron was announced in March. Since then, Rocket Lab’s been busy, going public via a merger with a blank-check firm, continuing to develop its Electron reusability program, and expanding its space services division. All the while, the company has managed to stay mum about Neutron – until now.

Carbon composites

Neutron features a number of surprising innovations that depart from other rockets of its class in both operation and development. The first is materials: the 131-foot rocket will be made out of a special carbon composite, much like its sibling rocket Electron.

It’s an interesting choice, particularly as SpaceX famously decided to ditch carbon composites for its Starship system in favor of stainless steel. But this is not Rocket Lab’s first rodeo with carbon composites; not only do they make up the bulk of the Electron rocket, Beck has been working with advanced composites and materials since the start of his career at a New Zealand government research facility.

“If you’re someone who is used to working in metallics, actually moving into composites is really challenging,” CEO Peter Beck told TechCrunch. “But if you’ve always been in composites and your experience is there, then actually, they’re pretty simple.”

Metallic structures are heavy and low-performance; while that can be made up for with high-performance engines, this doesn’t lead to high margins or high reliability for reuse, he added. Lighter structures avoid what he called “the rocket spiral of doom”: a never-ending arms race between heavier structures requiring more propellant, which then requires a larger propellant tank, which increases the weight and requires even more propellant — ad infinitum.

“This is the first time in my career ever, where the spiral of doom is inversed. The spiral of doom is inversed because of the lightweight structures, and it’s not just important from a launch perspective, it’s actually really important from a reentry perspective,” he said. Why? According to Beck, Neutron’s large diameter at 23 feet and light weight gives it a large ballistic coefficient, a measure of an object’s ability to resist air drag. So the focus on structure means using less propellant on reentry, less air drag (and less heat as a consequence), and a simpler engine.

The Neutron will also be finished in a new type of graphite composite for added thermal protection, a new addition that will be coming to future Electron rockets as well.

The ‘Hungry Hippo’

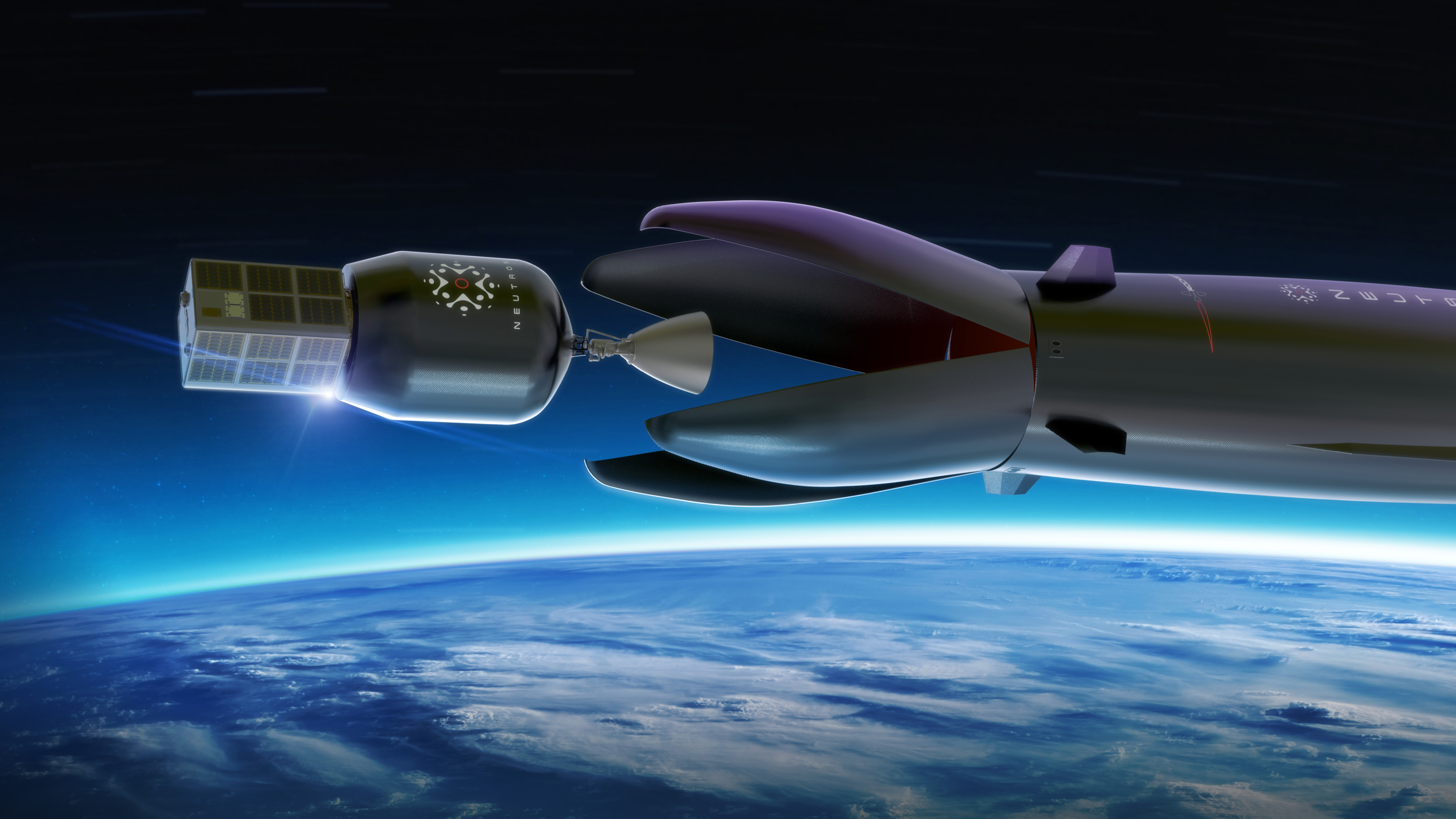

Another major departure from conventional rocket design are Neutron’s fairings, a piece of equipment that traditionally sits at the top of the rocket like a nose cone, protecting the payload inside. Historically, fairings separate and fall back to Earth and are generally considered expendable, though SpaceX retrieves them from the ocean for refurbishment and reuse.

Rocket Lab has instead attached the four fairings to the first stage, where they will mechanically open (imagine a strange, robotic flower). This is yet another design decision that has been driven by the use of composite materials, Beck said.

Image Credits: Rocket Lab (opens in a new window)

“Normally you don’t have the mass margins to be able to hold onto fairings and do things like that. You have to get rid of the fairings as quick as you can, because you can’t afford that parasitic mass. But when the parasitic mass is really low, then it allows you to be able to do these kinds of things.”

Neutron will be capable of carrying a maximum of 15,000 kilograms of payload to low Earth orbit, putting it right in competition with SpaceX’s Falcon 9 and Relativity Space’s in-development Terran R rocket.

But what about the second stage?

Not only is there no nose cone payload fairing, Rocket Lab also decided to overhaul the second stage as well. Conventional rocket design integrates the second stage by sandwiching it between the first stage and the payload. But with Neutron, the second stage will hang inside the first stage. When the rocket needs to deploy the payload, the ‘Hungry Hippo’ fairing design will open and release both the second stage and payload to orbit.

Rocket Lab intends to use Neutron for different types of missions, including human spaceflight. In the case of a crewed launch, Beck said they could simply remove the fairings and the capsule holding the crew would go on top.

The second stage is designed to be expendable. While other rocket companies are working on full reusability, Beck said the jury was still out on whether second stage reusability makes sense, particularly considering the increased mass requirements of reusability and the associated operational costs of recovery.

Returning to Earth

Once the second stage is deployed, the first stage will return to Earth to land right back on its launch pad. That means no touchdown on an ocean barge, another choice that will save on operational costs, Beck said.

Neutron will get to orbit and back using seven new engines Rocket Lab has developed, which it calls Archimedes. These low-pressure engines will run on liquid oxygen (LOX) and methane, rather than LOX and kerosene. Just like the decision to return the first stage to the launch site, the propellant choice was designed to minimize turnaround time between missions.

“Engines have typically in the past required a lot of refurbishment. And they require a lot of refurbishment because the propellants chosen have been LOX and kerosene. Kerosene creates a lot of sooting, a lot of coking,” he said. “So that’s what drove the decision to use methane, is that you can run an engine on methane and it’s perfectly clean and still shiny after you’ve finished burning it.”

Neutron will eventually take off from somewhere in the United States, and Rocket Lab is in the middle of a competitive process to choose a launch and manufacturing site. Much has been made of the auspicious absence of any specific launch date for Neutron – Rocket Lab had previously said 2024, which was not mentioned in this morning’s update – but Beck said that omission wasn’t intentional.

“We’re aiming to get one on the pad in ’24 and get a commercial customer up in the sky in ’25,” he confirmed. “But we also acknowledge it’s a rocket program. So it’s a lot of work to do but we’re working hard and that’s the plan.”

Rewatch the company’s Neutron update in here: